William Hackett Yoke Lifting Point Long Bolt - Metric Thread

- Rotates through 360° and pivots 90°.

- Manufactured from alloy steel, quenched and tempered.

- Manufactured and tested in accordance with EN1677-1.

- Certified by DGUV GS-OA 15-04.

- Load rated parts and cap screw are traceable to Test Certification.

- Bolts are Metric thread (ASME / ANSI B18.3.1M).

- Proof tested to 2.5 times the WLL.

- Fatigue rated to 1.5 times the WLL.

- Design Factor 4:1.

- All YOKE Lifting points meet or exceed all the requirements of ASME B30.26.

- Quick and simple assembly, just a tapped hole is required.

USES

- Suited for lifting objects with no obvious attachment points

- Mold and die handling

- Pump and valve handling

- Ideal for lashing attachment points

- Suitable for attachment to lifting beams and spreader beams

| Part Code | WLL tonnes | Torque in Nm | Bolt Size | Thread E (mm) | Mass kg |

| 8-211-003/105L | 0.30 | 30 | M8 | 76 | 0.4 |

| 8-211-006/125L | 0.63 | 60 | M10 | 96 | 0.4 |

| 8-211-010/150L | 1.00 | 100 | M12 | 114 | 0.5 |

| 8-211-015/185L | 1.50 | 150 | M16 | 149 | 0.7 |

| 8-211-025/230L | 2.50 | 250 | M20 | 187 | 1.7 |

| 8-211-040/265L | 4.00 | 400 | M24 | 221 | 2.0 |

| 8-211-050/340L | 5.00 | 500 | M30 | 279 | 2.9 |

| 8-211-080/300L | 8.00 | 800 | M36 | 222 | 6.9 |

| 8-211-100/350L | 10.00 | 1000 | M42 | 272 | 7.9 |

| 8-211-150/350L | 15.00 | 1500 | M42 | 264 | 13.5 |

| 8-211-200/385L | 20.00 | 2000 | M48 | 295 | 15.5 |

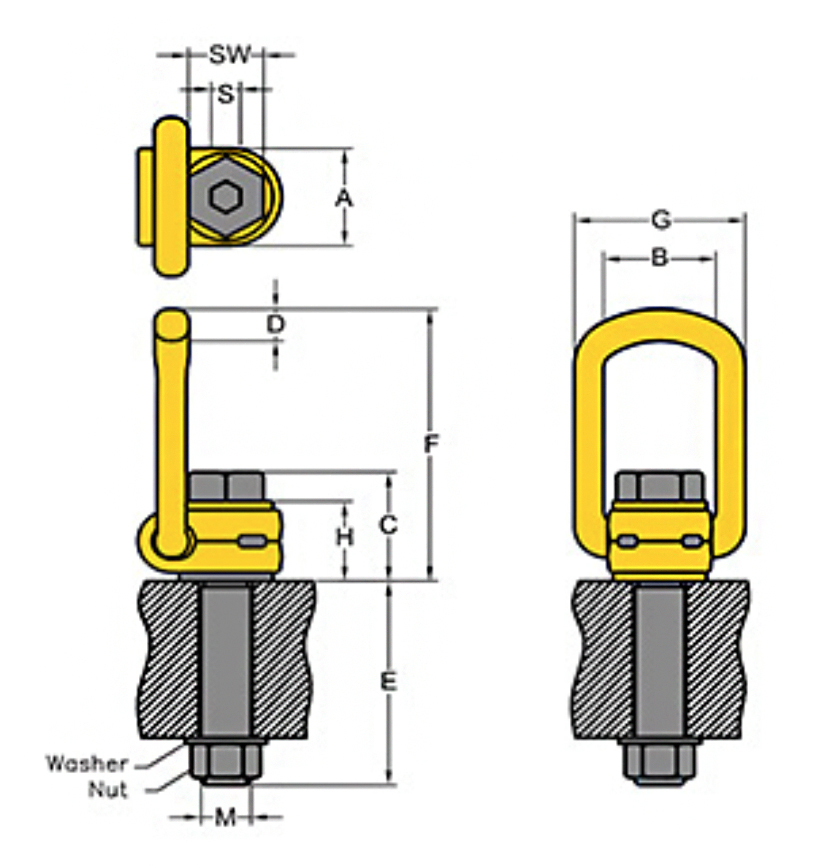

DIMENSIONAL SPECIFICATION

| WLL tonnes | Thread M (mm) | Thread E (mm) | Thread Pitch DIN13 | A (mm) | B (mm) | C (mm) | D (mm) | F (mm) | G (mm) | H (mm) | S (mm) | SW (mm) | Torque in (Nm) | Mass (kg) |

| 0.3 | M8 | 76 | 1.25 | 30 | 35 | 35 | 10 | 86 | 55 | 29 | 6 | 13 | 30 | 0.4 |

| 0.63 | M10 | 96 | 1.5 | 30 | 35 | 36 | 10 | 86 | 55 | 29 | 6 | 17 | 60 | 0.4 |

| 1.0 | M12 | 114 | 1.75 | 33 | 38 | 44 | 14 | 99 | 57 | 36 | 8 | 19 | 100 | 0.5 |

| 1.5 | M16 | 149 | 2 | 33 | 38 | 46 | 14 | 99 | 57 | 36 | 10 | 24 | 150 | 0.7 |

| 2.5 | M20 | 187 | 2.5 | 50 | 54 | 56 | 17 | 142 | 82 | 43 | 12 | 30 | 250 | 1.7 |

| 4.0 | M24 | 221 | 3 | 50 | 54 | 59 | 17 | 143 | 82 | 44 | 14 | 36 | 400 | 2.0 |

| 5.0 | M30 | 279 | 3.5 | 60 | 65 | 81 | 23 | 170 | 99 | 62 | 17 | 46 | 500 | 2.9 |

| 8.0 | M36 | 222 | 4 | 77 | 85 | 101 | 27 | 225 | 124 | 78 | 22 | 55 | 800 | 6.9 |

| 10.0 | M42 | 272 | 4.5 | 77 | 85 | 104 | 27 | 225 | 124 | 78 | 24 | 65 | 1000 | 7.9 |

| 15.0 | M42 | 264 | 4.5 | 95 | 104 | 112 | 36 | 258 | 158 | 86 | 24 | 65 | 1500 | 13.5 |

| 20.0 | M48 | 295 | 5 | 95 | 104 | 120 | 36 | 260 | 158 | 90 | 27 | 75 | 2000 | 15.5 |

LIFTING POINT WORKING LOAD APPLICATION FACTORS

|

|

|

|

|

|

|

|

|

|||

| Number of legs | 1 | 2 | 1 | 2 | 2 | 2 | 3-4 | 3-4 | ||

| Load direction | 0° | 0° | 90° | 90° | 0-45° | 45-60° | unsymm. | 0-45° | 45-60° | unsymm. |

| Thread | WLL tonnes | |||||||||

| M8 | 0.3 | 0.6 | 0.3 | 0.6 | 0.42 | 0.3 | 0.3 | 0.63 | 0.45 | 0.3 |

| M10 | 0.63 | 1.26 | 0.63 | 1.26 | 0.88 | 0.63 | 0.63 | 1.32 | 0.95 | 0.63 |

| M12 | 1.0 | 2.0 | 1.0 | 2.0 | 1.4 | 1.0 | 1.0 | 2.1 | 1.5 | 1.0 |

| M16 | 1.5 | 3.0 | 1.5 | 3.0 | 2.1 | 1.5 | 1.5 | 3.1 | 2.2 | 1.5 |

| M20 | 2.5 | 5.0 | 2.5 | 5.0 | 3.5 | 2.5 | 2.5 | 5.2 | 3.7 | 2.5 |

| M24 | 4.0 | 8.0 | 4.0 | 8.0 | 5.6 | 4.0 | 4.0 | 8.4 | 6.0 | 4.0 |

| M30 | 5.0 | 10.0 | 5.0 | 10.0 | 7.0 | 5.0 | 5.0 | 10.5 | 7.5 | 5.0 |

| M36 | 8.0 | 16.0 | 8.0 | 16.0 | 11.2 | 8.0 | 8.0 | 16.8 | 12.0 | 8.0 |

| M42 | 10.0 | 20.0 | 10.0 | 20.0 | 14.0 | 10.0 | 10.0 | 21.0 | 15.0 | 10.0 |

| M42 | 15.0 | 30.0 | 15.0 | 30.0 | 21.0 | 15.0 | 15.0 | 31.5 | 22.5 | 15.0 |

| M48 | 20.0 | 40.0 | 20.0 | 40.0 | 28.0 | 20.0 | 20.0 | 42.0 | 30.0 | 20.0 |